🔥 From Sparks to Safety : Understanding Fire Sprinklers

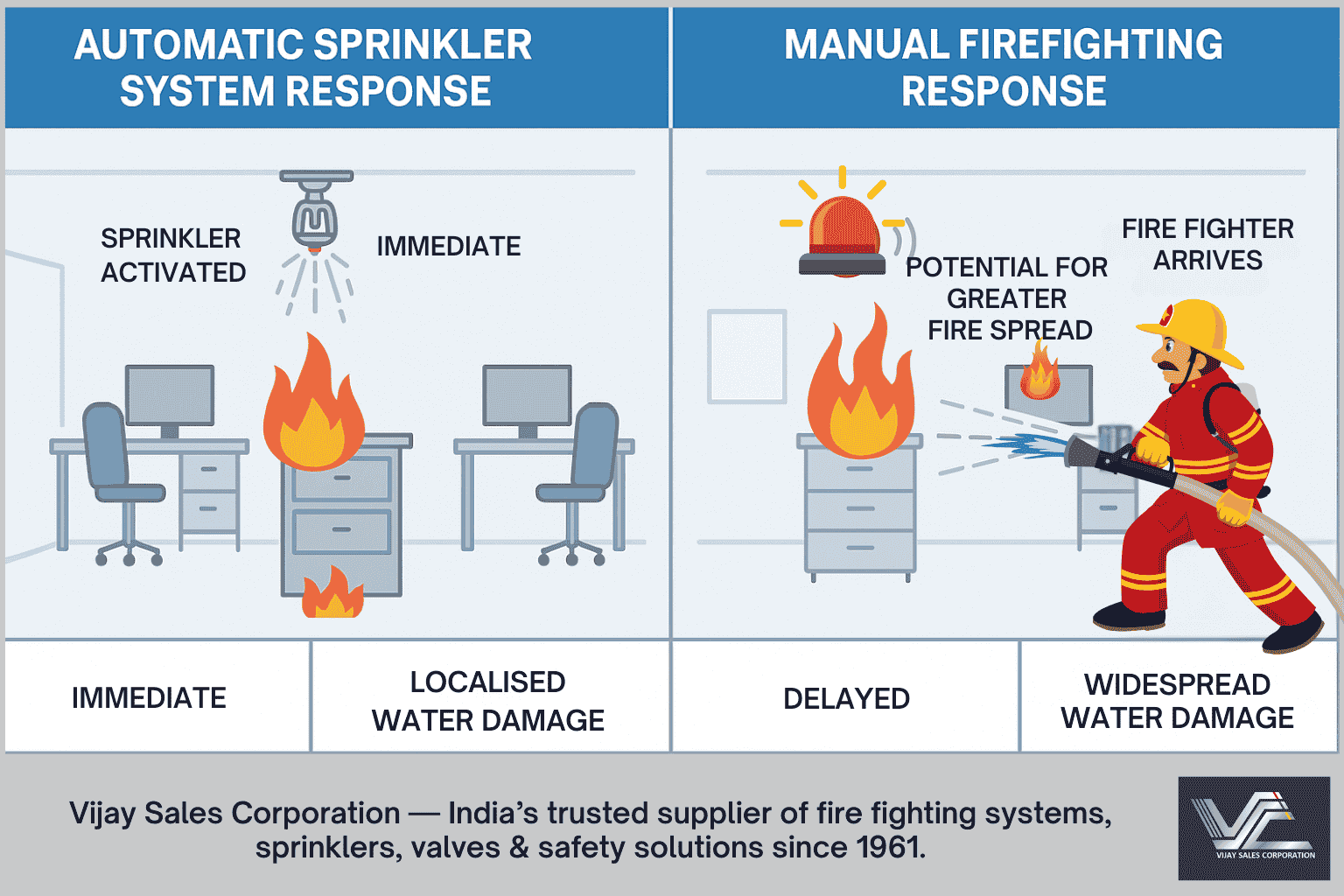

When Seconds Decide Everything

It always starts small.

A tiny spark in a warehouse corner. A cable short in a factory ceiling. A forgotten cigarette in a high-rise parking lot.

And in that single moment, the difference between devastation and control often comes down to one unsung hero — the fire sprinkler.

As someone who’s spent years walking through half-finished construction sites and humming factories, I’ve seen this story unfold more times than I’d like. I’ve seen the blackened remains of a production floor — melted machinery, charred walls — and then, a single unburnt section where a sprinkler had done its job perfectly. The workers called it “the lucky zone.” But luck had nothing to do with it. It was design, precision, and the choice to invest in reliability before disaster struck.

For contractors and builders, fire safety isn’t just a compliance checklist — it’s a responsibility that protects every nail, beam, and human life behind a project. For industrial maintenance heads and engineers, it’s the quiet assurance that the systems they approved will stand guard when no one else is watching.

And that’s what fire sprinklers really are: silent guardians.

They don’t boast. They don’t blink. But when the flames rise, they speak the loudest — through the steady hiss of water and the sigh of a fire being tamed.

This article is your inside look into how these simple-yet-sophisticated systems work, why they matter, and what makes them reliable. Whether you’re planning a commercial tower, running an industrial unit, or designing a fire safety network, this is where understanding fire sprinklers turns into mastering safety.

The Backbone of Fire Safety — Understanding Fire Sprinkler Systems

Imagine standing beneath a ceiling grid peppered with sprinkler heads. To most people, they look like tiny metallic flowers — harmless, decorative even. But within each one lies a life-saving mechanism, engineered to react in less than a heartbeat.

Here’s the magic:

Fire sprinklers don’t wait for smoke. They respond to heat — specifically, when the surrounding temperature crosses a threshold (often around 68°C to 74°C). Inside each sprinkler is a small glass bulb filled with a heat-sensitive liquid. As the temperature rises, the liquid expands. When it gets hot enough, the bulb bursts, releasing a jet of pressurized water.

It’s a simple principle — but executed with stunning precision.

That’s why, in real-world tests, a well-designed sprinkler system can control or extinguish 90% of fires before firefighters even arrive.

Let’s break it down: the core components that make this possible

-

The “sentries” that detect heat and discharge water.

-

The hidden veins carrying pressurized water throughout the building — often made of GI Pipes at Vijay Sales Corporation, known for their corrosion resistance and strength.

-

The “command center” that governs water flow and ensures consistent pressure.

-

The messengers that trigger alarms and alert systems when the sprinklers activate.

-

The heart that keeps the pressure alive, ensuring water reaches even the farthest point of the network.

Each part plays its role — and like an orchestra, they must be perfectly in tune. A weak valve or a corroded pipe doesn’t just slow the response — it risks everything.

I once visited a textile plant in Ludhiana where a tiny fault in a control valve delayed sprinkler activation by a mere 14 seconds. Fourteen seconds — that’s how long it took for one machine to catch another, turning a localized fire into a ₹20-lakh loss. Afterward, the project manager said something that stuck with me:

“We used to think fire systems were expenses. That day, we realized they’re insurance.”

That’s the truth about fire sprinklers — they don’t just protect your property; they protect your reputation. They keep your contracts intact, your workforce safe, and your deadlines on track.

In the sections ahead, we’ll explore the different types of fire sprinkler systems, what materials work best, and how design decisions can make or break your fire safety setup. But first, remember this:

A fire sprinkler system is only as strong as its smallest part.

And ensuring that every nut, bolt, and pipe is up to standard — that’s where reliability begins.

Types of Fire Sprinkler Systems — One Size Doesn’t Fit All

If there’s one thing every contractor learns early, it’s this — no two projects are alike.

A hospital’s safety needs aren’t the same as a steel plant’s. A corporate tower doesn’t face the same risks as a cold storage facility. Yet, every one of them depends on one common factor — fire sprinklers that are tailored to their environment.

Think of sprinkler systems as different tools in the same safety toolbox. The key is choosing the right one for the job. Let’s break them down, the way an engineer would explain them on-site.

Wet Pipe Systems – The Reliable Workhorse

Picture this: a line of GI Pipes at Vijay Sales Corporation filled with water, constantly pressurized, waiting quietly behind the walls and ceilings.

That’s your Wet Pipe System — the simplest, most commonly used setup in offices, hotels, and residential complexes.

How it works:

When the glass bulb in a sprinkler head bursts, water flows instantly — no delay, no extra mechanism. It’s instant action against heat.

Where it fits best:

· Office buildings

· Shopping complexes

· Residential apartments

Why contractors love it:

· Easy installation

· Low maintenance

· Quick activation

Story from the field:

A builder in Gurugram once told me, “We sleep well only when we know the sprinklers are wet.” His team had chosen a wet pipe system for a 20-storey commercial tower. Two years later, a short-circuit caused a fire in the basement parking. Within seconds, the sprinklers kicked in and confined the fire to a single car.

That’s what reliability looks like — no drama, just precision.

Dry Pipe Systems – The Cold Climate Defender

Now, imagine you’re working on a warehouse in Himachal or a cold storage unit near Delhi. The temperatures drop. Water can freeze inside pipes.

That’s where Dry Pipe Systems step in — air-filled pipes that release water only after the sprinkler head activates.

How it works:

The pipes are filled with pressurized air. When heat triggers a sprinkler head, the air escapes, opening a valve that allows water to rush in.

Where it’s used:

· Cold storage units

· Parking basements

· Unheated warehouses

Advantages:

· Prevents freezing

· Reduces pipe corrosion

· Ideal for temperature-sensitive environments

Example:

A food logistics company near Baddi installed a dry pipe system for its frozen goods facility. During a small electrical spark incident, the system performed flawlessly — no frozen pipes, no blockages, and no loss of stock.

The project manager summed it up well:

“It’s not just about fighting fire. It’s about staying ready when the weather isn’t.”

Deluge Systems – The Heavy-Duty Protector

When dealing with high-risk zones — like refineries, power plants, or chemical units — you can’t afford hesitation. Enter the Deluge System.

How it works:

All sprinkler heads stay open, and when a fire detection system senses danger, a control valve opens, flooding the area instantly.

It’s not a “one-head-at-a-time” response — it’s an all-out attack.

Where it’s used:

· Refineries

· Power plants

· Industrial production floors

Why it matters:

· Maximum coverage

· Fast suppression for high-hazard fires

Analogy:

Think of it as the “fire brigade inside your building.” Instead of waiting for the flames to grow, the deluge system rains down before things spiral out of control.

Pre-Action Systems – The Intelligent Guardian

Now comes the most sophisticated type — the Pre-Action System.

This setup combines detection with decision-making. It’s designed for places where even an accidental water discharge could be disastrous — like server rooms, data centers, or art galleries.

How it works:

The system fills with water only after a fire is confirmed by heat or smoke detection. That means no accidental soaking due to false alarms.

Where it’s used:

· IT data centers

· Museums or archives

· Laboratories and control rooms

Why it’s preferred:

· Dual verification: only releases water when it’s absolutely necessary

· Prevents equipment damage

· Ensures safety with precision

Case in point:

At an IT park in Pune, a contractor installed a pre-action system using Industrial Valves from Vijay Sales Corporation to ensure zero leaks.

Months later, a small server room fire triggered the system — precise, fast, and effective — with no unnecessary flooding. That single project led to five new referrals.

Each of these systems is built around the same purpose — to control chaos before it spreads.

Choosing the right one isn’t about guessing. It’s about understanding your project’s risks, environment, and infrastructure. And for that, the right combination of expertise and certified materials makes all the difference.

Choosing the Right Materials — Why Pipes, Valves, and Fittings Matter

Let’s be honest — most fires don’t fail to get controlled because of missing sprinklers.

They fail because the materials behind the sprinklers couldn’t handle the pressure when it mattered most.

I remember a conversation years ago with a site engineer at a textile factory in Panipat. He looked exhausted, surrounded by burnt fabric rolls and twisted metal pipes. When I asked what happened, he sighed and said:

“The sprinklers worked. The water didn’t.”

His team had unknowingly installed poor-quality pipes and valves that couldn’t withstand pressure during activation. When the sprinklers opened, one flange joint burst open. Water gushed everywhere — except where it was needed. That single failure cost the company crores in damages.

It’s stories like this that remind every experienced contractor and project engineer of one truth:

A fire fighting system is only as strong as the material it’s built from.

1. Pipes — The Arteries of Your Fire Safety System

Think of pipes as the veins and arteries that carry the lifeblood of your sprinkler network — water.

If they’re weak, corroded, or unapproved, the entire system collapses under pressure.

Best Materials for Fire Sprinkler Networks:

| Pipe Type | Application | Why It's Preferred |

|---|---|---|

| GI Pipes at Vijay Sales Corporation | Most commercial and industrial projects | Excellent corrosion resistance, strong, and IS-marked reliability |

| MS Pipes | Pump rooms, riser mains | Durable and easy to weld, suitable for high-pressure zones |

| Seamless Pipes | Hazardous or high-pressure systems | No welds = no weak points; perfect for refineries or plants |

Real Project Insight:

A Delhi-based contractor recently switched to Jindal Star GI Pipes for an industrial project after multiple failures with local brands. The result? Zero leakages during hydro testing and faster project clearance from safety inspectors.

Takeaway:

Don’t think of pipes as metal tubes — think of them as your system’s lifeline. When you choose branded, IS-marked pipes, you’re not just meeting code — you’re ensuring performance when pressure peaks.

2. Valves — The System’s Control Room

If pipes are the veins, valves are the heart and brain.

They control water flow, direct pressure, and decide how your sprinkler system responds during a crisis.

A single malfunctioning valve can ruin a flawless design.

That’s why professionals trust tested brands like Sant Valves, Castle Valves, and Advance Valves — brands known for precision, durability, and IS certification.

Common Types Used in Fire Systems:

· Gate Valves: Isolate sections during maintenance.

· Butterfly Valves: Offer quick shut-off control.

· NRVs (Non-Return Valves): Prevent backflow and pressure drop.

· Alarm Valves: Trigger alarms upon activation of the sprinklers.

Field Example:

A hospital in Lucknow experienced a fire in its basement. The sprinkler system activated perfectly because of a Sant Butterfly Valve that maintained flawless water pressure across all floors. The chief engineer later said:

“We used to look at valves as accessories. Now we treat them like critical equipment.”

Pro Tip:

Always verify IS:780 and IS:13095 certifications for valves in fire applications. Inferior valves often fail during hydrostatic testing — costing both money and credibility.

👉 Explore durable, certified Industrial Valves at Vijay Sales Corporation.

3. Fittings and Flanges — The Unsung Connectors

These small components often don’t get the attention they deserve, yet they’re where most leaks begin.

Common Types Used in Fire Systems:

· Flanges: For secure pipe connections and maintenance flexibility.

· Elbows, Tees, and Reducers: For layout and direction control.

· Threaded or Welded Fittings: Depending on pressure ratings and space.

Why Quality Matters:

Even a tiny crack in a flange or a low-grade fitting can turn into a leak under 12-bar testing pressure — and when that happens during an actual fire, there are no second chances.

That’s why smart contractors prefer tested and branded Flanges and GI Fittings from trusted suppliers who maintain consistent quality.

Example from the Field:

During a hydro test at a large manufacturing plant in Noida, an imported low-cost flange cracked at 9 bar. The team replaced it with a VS-branded flange from Vijay Sales Corporation — it held firm at 14 bar.

That’s the difference between theory and real-world reliability.

When it comes to fire fighting, every component — whether visible or hidden — tells a story of protection, trust, and precision.

Contractors who focus on quality materials don’t just build systems — they build confidence. And that confidence is what keeps both buildings and businesses standing long after the smoke clears.

🔥 Explore Our Fire Fighting Range

At Vijay Sales Corporation, we supply IS-marked and trusted fire safety materials — from NewAge Sprinklers to Lifeguard Fire Extinguishers, ensuring complete protection for every project — whether commercial, residential, or industrial.

NewAge Fire Sprinklers

Automatic sprinkler systems for rapid fire response and safety assurance.

Lifeguard Fire Extinguisher

Reliable, portable extinguishers trusted by builders and industrial users.

Jindal Star GI Pipes

IS-marked galvanized pipes offering superior corrosion resistance and durability.

Vijay Sales Corporation — Protecting India’s Projects Since 1961

Installation & Testing — The Final Frontier

Even the best-designed fire sprinkler system is only as good as its installation and testing.

You can have Jindal GI pipes, Sant Valves, and perfectly machined flanges — but if the installation isn’t done right, the system may never get a chance to prove its worth when it truly matters.

I’ve often said to contractors during site walkthroughs:

“A sprinkler system doesn’t fail in the fire — it fails during installation.”

Why Installation Is the Silent Deal-Maker

Installing a sprinkler system isn’t about connecting pipes and tightening bolts. It’s about creating a living network — one that can sense danger, react instantly, and deliver consistent water pressure across every floor, every corner, and every nozzle.

Picture this: a 15-floor commercial building in Gurugram.

The contractor used premium materials — GI Pipes at Vijay Sales Corporation, Sant Valves, and cast flanges. But during commissioning, a small oversight — a slightly tilted pipe — led to trapped air pockets in the main riser. When tested, a section of the sprinklers failed to activate. It took just one mistake, smaller than a pencil’s width, to delay water discharge.

That’s why testing is not an afterthought — it’s the final inspection that separates reliable systems from risky ones.

1. The Right Way to Install a Fire Sprinkler System

Every installation follows a rhythm — a mix of planning, precision, and patience.

-

· Confirm drawings match site dimensions.

· Ensure correct spacing between sprinklers (typically 2.4–3.6 meters apart).

· Verify ceiling height and heat zones for accurate sprinkler placement.

-

· Use IS-marked pipes and genuine Industrial Valves.

· Maintain correct slope for drainage.

· Properly anchor risers to prevent vibration or joint stress.

-

· Fit flanges tightly — but avoid over-tightening bolts.

· Test alignment visually and with gauges before welding.

· Mark all control valves clearly (OPEN/CLOSE indicators are critical).

-

· Flush the system thoroughly to remove debris or scale.

· Label every zone and test line flow.

· Coordinate with the electrical team for alarm and signal integration.

2. Hydrostatic Testing — Where Reliability Gets Proven

This is where you see if the system truly holds up under pressure — literally.

What Hydro Testing Means:

It’s a high-pressure water test conducted to check for leaks, cracks, and joint strength.

The system is filled with water and pressurized (usually up to 1.5 times the design pressure).

Ideal Testing Pressure:

· For standard buildings: 10–12 bar

· For industrial units or high-rises: 14–16 bar

Testing Checklist:

· Close all drain valves before pressurization.

· Keep the test pressure constant for at least 2 hours.

· Inspect every joint, valve, and flange visually for leaks.

· Record pressure readings — maintain documentation for inspection.

A Real-Life Lesson:

At a factory site in Manesar, a contractor rushed testing to meet a handover deadline. One untested elbow joint failed during an actual fire months later, flooding the electrical panel room. The cost? ₹35 lakhs in repair and downtime.

After that, their company made hydrotesting a mandatory, logged process.

As one of their engineers later said,

“We no longer look at testing as a task. It’s our guarantee to the client.”

3. Regular Maintenance: The Long-Term Shield

A sprinkler system is not “fit and forget.”

It needs regular checks, just like any machinery or safety system.

Monthly Maintenance Must-Dos:

· Inspect all valves for corrosion or leak signs.

· Test water flow switches.

· Check gauges for correct pressure.

· Flush test connections every quarter.

· Ensure alarm valves and control valves are accessible and tagged.

A client from an industrial park in Pune told me that his maintenance checklist was once a “formality.” After a small compressor room fire, that checklist became his most valuable document. The sprinklers had done their job perfectly — because the team had been doing theirs too.

Installation and testing are where engineering meets trust.

When a system passes its hydro test, it’s more than just a technical success — it’s a silent promise.

A promise that when the alarm rings and the first spark flares, your system will rise to the occasion, not crumble under it.

That’s why builders and contractors who get this stage right rarely face rework, repair calls, or failed inspections. They build not just safer structures — but stronger reputations.

Common Installation Mistakes — and How to Avoid Them

Every contractor or site engineer has that one project that taught them a hard lesson. Mine was a manufacturing unit outside Faridabad — spotless, state-of-the-art, and freshly commissioned. Everything looked perfect until the final test. When the fire pump started, the main riser shook violently, and within seconds, a flange joint burst open like a pressure cooker lid.

That day I learned something I’ve never forgotten:

Here are the most common mistakes that creep into even the best projects — and how you can avoid them before they become expensive (or dangerous) lessons.

1. Undersized Pipes — The Hidden Choke

Choosing smaller pipes to cut costs or save space might look smart on paper. But when water surges through during an emergency, undersized lines choke flow and delay activation.

Typical Scenario: A builder uses 25 mm branch lines instead of the recommended 32 mm for sprinkler drops. Result — weak discharge pressure, uneven coverage, and failure to meet IS flow requirements.

Avoid It:

- Always follow pipe sizing charts.

- For most projects, prefer GI Pipes at Vijay Sales Corporation — they maintain consistent internal diameter and meet pressure specifications.

2. Using Unapproved or Fake ISI Materials

This is the most dangerous shortcut of all. Low-cost, unapproved pipes and fittings might look identical — but they’re disasters waiting to happen.

Avoid It:

- Source only IS-marked valves, flanges, and fittings from trusted brands like Sant, Castle, and NewAge.

- Verify the embossing on pipes and IS number — fake markings often differ in font or depth.

- Keep a material verification log before installation.

When it comes to fire systems, one fake component can burn through years of your reputation.

3. Incorrect Valve Orientation

It’s surprisingly common — a control valve installed upside down, or a check valve mounted against flow direction. During pressure testing, it might still pass — but during a real emergency, it simply won’t open.

Avoid It:

- Train your teams to double-check arrow indicators on valve bodies.

- Use Industrial Valves with clear flow direction marking and nameplate details.

- Label every valve “OPEN / CLOSE” and maintain a valve tag register.

4. Missing Drain Points and Air Release Valves

Air pockets are the silent enemies of fire systems. They prevent full water flow during activation and reduce pressure dramatically — especially in high-rise pipelines.

Avoid It:

- Install drain points at low levels and air release valves at the highest points.

- Flush every riser before pressure testing.

- Maintain a small slope in horizontal pipes to guide trapped air toward release points.

5. Poor Quality Control During Welding or Threading

Improper threading or incomplete welds often lead to micro leaks that only appear under high pressure. During a fire, these small leaks quickly turn into full bursts.

Avoid It:

- Use proper thread sealants — not Teflon tape alone.

- Always regrind welds after the first coat and conduct visual inspection.

- Keep a third-party quality inspection for every 100 joints.

6. Skipping Routine Maintenance and Re-Testing

This one’s the slow killer. A perfectly installed system can still fail if it’s never checked again after commissioning. Dust, scale, or corrosion may silently build up in the pipes.

Avoid It:

- Schedule periodic inspections — quarterly flow tests, annual hydro tests.

- Keep pump motors serviced and diesel engines tested.

- Replace corroded or seized valves immediately.

A fire sprinkler system isn’t just installed once — it’s maintained for life.

We Don’t Just Supply Materials — We Build Confidence

Whether you’re designing a pump room, installing sprinklers, or commissioning an industrial valve system, Vijay Sales Corporation ensures your materials are ISI-marked, pressure-tested, and field-proven.

We work hand-in-hand with project engineers, contractors, and fire consultants across India — helping them avoid the mistakes you just read about.

Need a quick quote or expert guidance?

Reach us instantly on WhatsApp or explore our certified product range below.

Serving India’s industrial, commercial, and infrastructure projects since 1961 —

Vijay Sales Corporation — where quality builds safety.