JCO Pipes – Heavy-Duty Longitudinal Welded Pipes for Structural & Line Applications

JCO Gas Pipe Limited

Vijay Sales Corporation is proud to be a leading supplier of JCO Gas Pipe Ltd.’s Spiral SAW Pipes, which are at the forefront of the piping industry. JCO specializes in manufacturing Spiral SAW Pipes that span a range from 406 mm to a notable 1626 mm diameter, with wall thicknesses varying from 5mm to 25mm. These pipes are manufactured in compliance with IS 3589: 2001, IS: 5504, API-5L, and ASTM standards, ensuring they meet the rigorous quality and safety expectations of our clients.

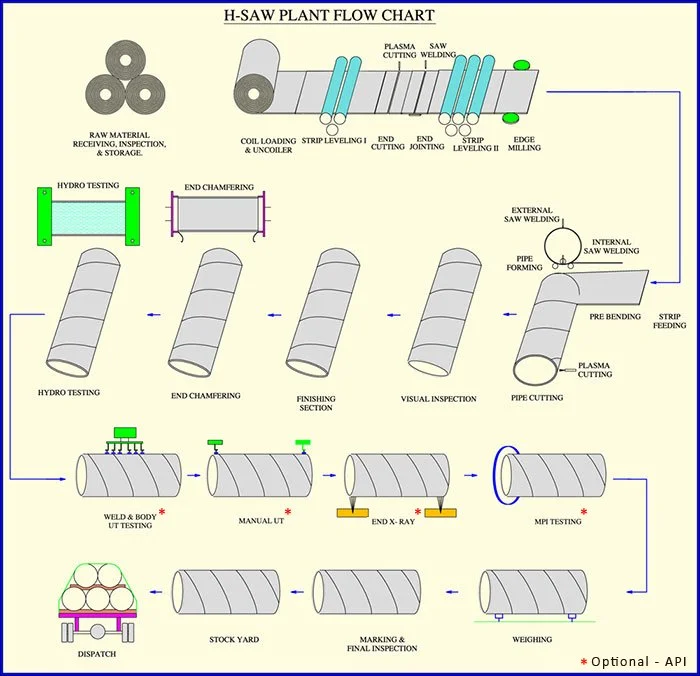

Advanced Manufacturing Process

The production process of Spiral SAW Pipes begins with high-quality H.R. Coil, which forms the raw material base. The manufacturing journey of each pipe is a testament to precision engineering:

Entry Line: Here, the coils are unwound and edge milled to precise widths, before being fed into the forming stand at uniform speed. This stage is critical as it involves the meticulous joining of the coil ends to produce continuous strips, with the helical angle adjusted for the spiral welding process.

Forming Stand: Known as the heart of the mill, this is where the magic happens. The strip is expertly formed to the specified size and spirally welded, embodying the core of JCO’s manufacturing excellence.

Exit Line: Serving a crucial role, the exit line provides support to the forming pipe, cuts it to the required length, and ejects it for further inspection.

Each pipe undergoes a thorough visual inspection inside and out for weld defects such as undercutting or porosity. Any issues are rectified in accordance with the approved Quality Assurance Plan (QAP). The pipes then proceed to beveling for precise joint quality, essential for seamless laying at the site. To guarantee zero leakage, the pipes are subject to hydrostatic testing, scrutinizing the integrity of both the weld joint and parent material.

To ensure that every pipe meets JCO's and our high-quality standards, inspections occur at various production stages, including physical, visual, destructive, and non-destructive testing, culminating in a final inspection before dispatch. This level of meticulous quality control positions Vijay Sales Corporation as the supplier of choice for Spiral SAW Pipes in India.

JCO pipes, distributed by Vijay Sales Corporation, are the preferred choice for projects demanding the highest standards of strength, durability, and reliability. Whether it’s for critical infrastructure, robust industrial use, or sophisticated energy projects, our pipes stand as pillars of development across India.

We invite you to explore our extensive range of JCO Spiral SAW Pipes, each crafted with the commitment to excellence that has become synonymous with the Vijay Sales Corporation name. Connect with us to discuss how our pipes can support your next project's success.

Application of JCO MS Spiral Saw Pipes -

JCO pipes are versatile and serve a multitude of applications across various industries:

Water Systems: Ideal for distribution and transmission lines, irrigation, portable drinking water, and power plant usage.

Structural Projects: Perfect for well casing, structural columns in high-rise buildings, piling, and casing pipes.

Industrial Applications: Essential for cooling water lines, drainage systems, smokestacks, mining operations, dredging, and air duct piping.

Oil & Gas Sector: Reliable for offshore & onshore pipelines, submarine pipelines, and structural components for offshore rigs, as well as cross-country and terminal piping projects.

Advanced Coating Techniques

At Vijay Sales Corporation, our partnership with JCO Gas Pipe Ltd. ensures access to a suite of advanced coating techniques, designed to significantly enhance the longevity and performance of our pipes. Recognizing that the protection of steel is paramount in extending the service life of our products, we offer an array of coating options, each tailored to meet the rigorous demands of various environments and applications.

Liquid Epoxy Coatings: These coatings are renowned for their excellent adhesion, corrosion resistance, and durability. Applied to both the interior and exterior surfaces of pipes, liquid epoxy coatings form a tough barrier against moisture and chemicals, making them ideal for pipes used in water supply and wastewater treatment plants.

Cement Mortar Lining (CML): This method involves the application of a cement mortar coating to the interior of our pipes. CML is highly resistant to the alkaline materials found in concrete and soil, providing superior protection against corrosion. This technique is particularly effective in prolonging the life of pipes used in potable water and sewage systems.

Guniting (External Cement Coating): Also known as shotcrete, guniting involves spraying a mixture of cement and sand at high velocity over the exterior of pipes. This creates a dense, impermeable layer that shields against aggressive ground conditions and physical impacts. It's widely used in underground applications where pipes are laid.

Coal Tar Tape Coating: This traditional method utilizes the water-resistant properties of coal tar combined with the mechanical strength of tape wrap to provide robust protection against harsh soil conditions. It's an excellent choice for buried pipes where moisture and corrosive agents are prevalent.

Epoxy Based Painting: Applied as a topcoat over primed steel, this type of paint is infused with epoxy resins, providing a resilient coating that stands up well to environmental and industrial stresses. It's an ideal selection for steel pipes exposed to harsh weather conditions or chemical processes.

External Varnish: To prevent rust during storage and transport, a thin layer of varnish can be applied to the pipe's exterior. This varnish layer acts as a temporary shield, protecting the steel from the elements until it reaches its final destination and is ready for installation.

Each of these coatings adheres to the stringent specifications laid out by Indian Standards (IS), the International Organization for Standardization (ISO), and the American Water Works Association (AWWA). Our adherence to these standards ensures that our coated pipes provide optimal protection against corrosion, wear, and extend the operational lifespan of the infrastructure they become a part of.

At Vijay Sales Corporation, we understand that the right coating can make all the difference in the effective and efficient transportation of resources. That's why we are committed to offering coatings that not only meet the current industry standards but also anticipate the needs of tomorrow's developments.

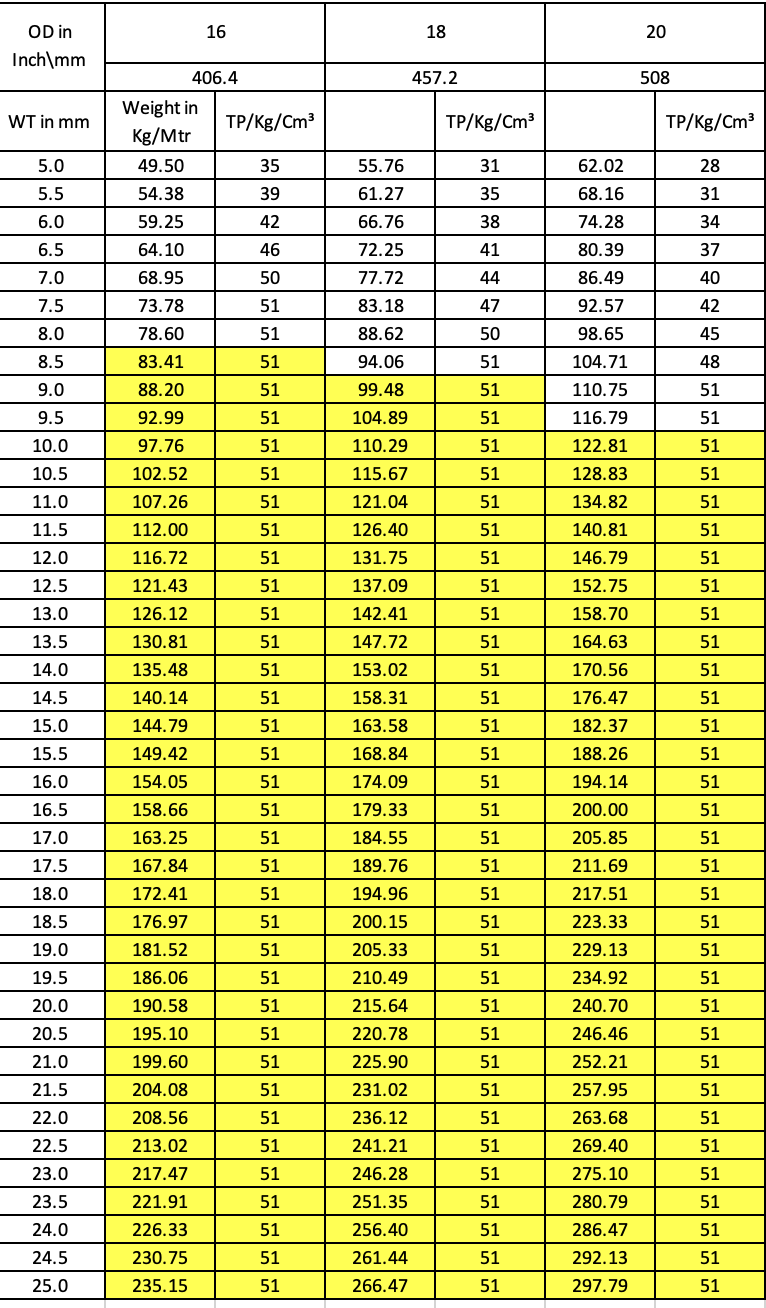

Weight in Kgs. per Running mtr & its Corresponding Test Pressure

JCO Gas Pipes: Delivering Quality, Reliability, and Versatility for Your Gas Piping Needs

Introduction

The demand for robust and superior gas piping solutions is paramount in the dynamic world of construction and infrastructure. At Vijay Sales Corporation, we proudly uphold our partnership with JCO Gas Pipes, a distinguished manufacturer celebrated for its commitment to quality and innovation.

For decades, JCO Gas Pipes has stood as a beacon of trust in the industry, offering advanced gas piping products that adhere to stringent quality and performance standards. As a top distributor of building materials, Vijay Sales Corporation is the go-to source for those in search of premier gas piping solutions.

The JCO Gas Pipes Advantage

Quality and Reliability: A Cornerstone of Excellence

JCO Gas Pipes is renowned for its rigorous adherence to international standards of quality and safety. Each pipe undergoes stringent testing to ensure it meets the certifications of ISO, API, and ASTM standards. These pipes are crafted from premium-grade steel and through advanced manufacturing techniques ensure superior durability and performance.

Diverse Product Range: Catering to Every Need

JCO Gas Pipes offers a comprehensive range of Spiral Submerged Arc Welded (HSAW) pipes, which are celebrated for their strength and resistance to corrosion. These characteristics make them ideal for a wide variety of gas piping applications.

Key Features of HSAW Pipes:

High Strength and Durability: Crafted to withstand high pressure and adverse environmental conditions.

Corrosion Resistance: Enhanced longevity and maintenance-free performance in harsh environments.

Installation Efficiency: Designed for quick and easy installation, reducing time and labor costs.

Versatility: Suitable for residential, commercial, industrial, and specialized applications.

| Diameter Range | Wall Thickness | Applications |

|---|---|---|

| 16" to 64" | 5mm to 25mm | Gas, Oil, Water |

| Sector | Applications |

|---|---|

| Residential | Home heating and cooking gas supply systems |

| Commercial | Gas supply for restaurants and office buildings |

| Industrial | Fuel lines for manufacturing plants |

| Specialty | Offshore drilling platforms and refineries |

The Vijay Sales Corporation Advantage

Competitive Pricing: Delivering Value without Compromise

Our strong relationships with manufacturers like JCO enable us to offer competitive pricing on high-quality gas pipes, ensuring our clients receive unparalleled value for their investments.

Expert Advice: Guiding You to the Right Solution

Our team’s deep expertise ensures that every client finds the perfect product for their specific needs, providing guidance from pipe selection to installation.

Wide Availability: Ensuring Prompt Delivery

We maintain a broad inventory of JCO Gas Pipes in various sizes and specifications to meet immediate client demands, ensuring swift project progression.

Exceptional Customer Service: Putting You First

We prioritize customer satisfaction, offering responsive service and comprehensive support throughout the sales and installation process.

Additional Considerations for Gas Piping Projects

When embarking on a gas piping project, consider these essential aspects:

Pressure Rating and Pipe Diameter: Crucial for ensuring safety and functionality.

Material Specifications: Key for achieving the desired durability and performance.

Installation Considerations: Best handled by certified professionals to adhere to safety standards.