Reliable Pipe Sealing for Concrete Structures

When pipelines pass through concrete, even a small leakage can compromise an entire structure.

That’s where Puddle Flanges come in — they form a watertight barrier, preventing seepage and protecting both the pipe and the concrete integrity.

At Vijay Sales Corporation, we manufacture and supply Mild Steel (MS) and Hot-Dip Galvanized Mild Steel (GI) Puddle Flanges that combine dimensional accuracy, welding precision, and verified material quality to deliver long-term performance in civil and industrial applications.

MS & GI Puddle Flanges – Vijay Sales Corporation

The Role of Puddle Flanges in Civil and Industrial Design

A puddle flange is not merely a fitting — it’s a structural safety feature.

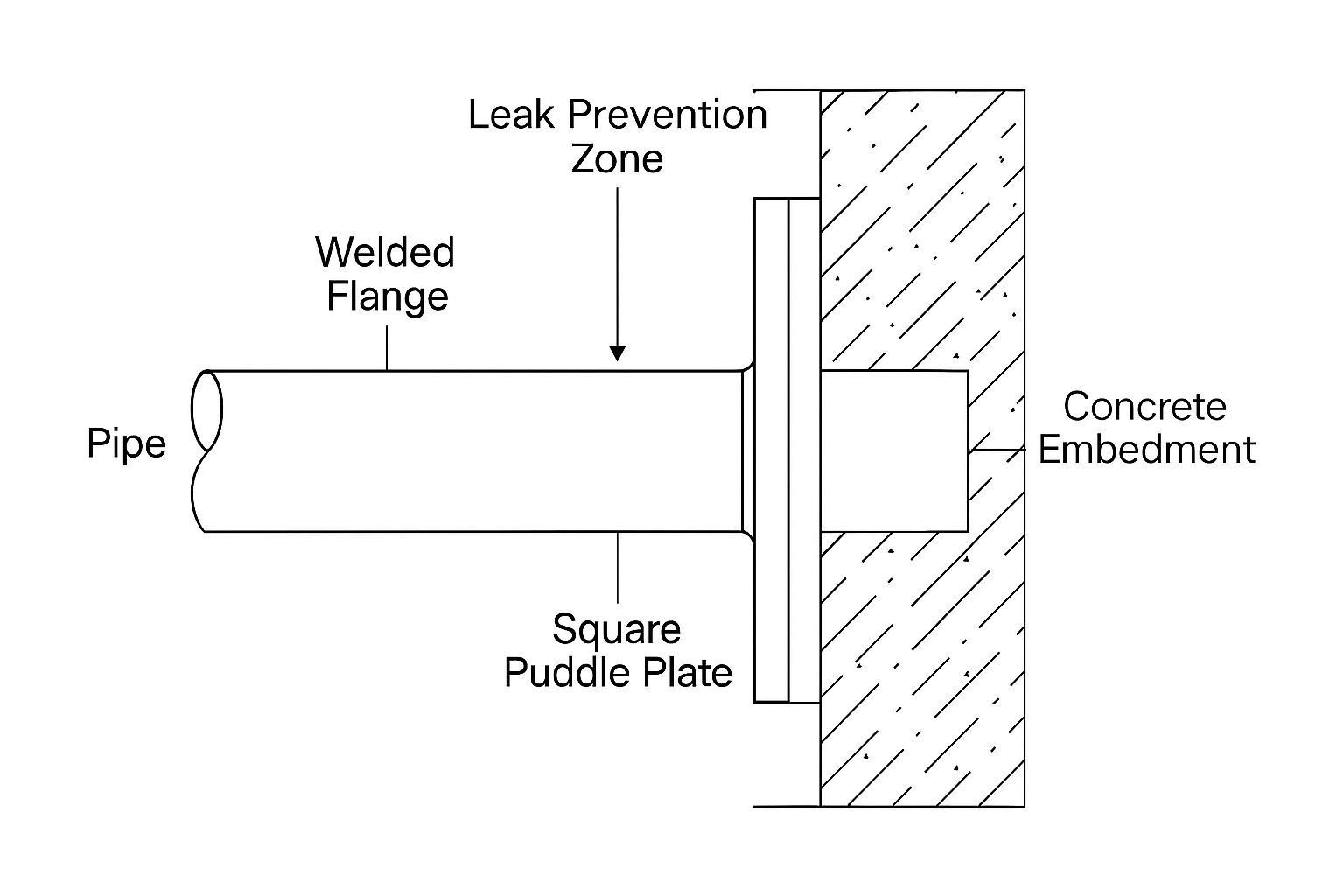

It’s welded to a pipe section that passes through a concrete wall, creating a mechanical seal that blocks water from tracking along the outer pipe surface.

In underground reservoirs, tanks, basements, and STPs, this seal is the difference between a leak-free installation and costly structural degradation.

Applications where Puddle Flanges are Critical:

RCC water tanks and sumps

Underground fire-fighting pipelines

Basement walls and retaining structures

Sewage treatment plants and manholes

Water and utility tunnels

The Material Advantage: MS & GI Only

Every environment has its own demands — and selecting the right material determines system longevity.

Mild Steel (MS):

High weldability ensures strong, distortion-free joints during fabrication.

Excellent dimensional stability under embedded loads.

Cost-effective and widely compatible with both threaded and flanged systems.

Common in fire-fighting, drainage, and internal water pipelines.

Galvanized Mild Steel (GI):

Coated via hot-dip galvanizing (zinc thickness 80–120 microns).

Provides long-term corrosion protection in buried or moisture-prone conditions.

Suitable for underground and external RCC penetrations.

Resistant to scaling and oxidation.

| Property | Mild Steel (MS) | Galvanized Mild Steel (GI) |

|---|---|---|

| Material Grade | IS 2062 | IS 4736 |

| Corrosion Resistance | Moderate | Excellent |

| Surface Finish | Painted / Epoxy | Hot-Dip Galvanised |

| Recommended Use | Internal pipelines, basements | Underground or exposed environments |

Technical Specifications

The following details represent the typical fabrication and supply scope for our Mild Steel (MS) and Galvanized Mild Steel (GI) puddle flanges.

Non-standard sizes, pressure ratings, and coatings can be manufactured as per project drawings or consultant requirements.

| Parameter | Typical Specification |

|---|---|

| Material | Mild Steel / Hot-Dip Galvanized Mild Steel |

| Size Range | 25 mm NB to 600 mm NB (custom sizes available) |

| Fabrication Type | Locally fabricated to match site dimensions and drawing requirements |

| Coating | Red Oxide Primer / Epoxy Coating / Hot-Dip Galvanised Finish |

| Flange Type | Plain End / Threaded / Welded |

| Pressure Range (Indicative) | Suitable for non-pressure and low-pressure applications (up to PN 10) |

| Tolerances | ±1 mm (dimensional), visual weld inspection performed on all pieces |

| Testing (on request) | Visual, Dimensional, and Coating Thickness Verification |

Engineering and Quality Assurance

Every puddle flange supplied by Vijay Sales Corporation follows a controlled manufacturing sequence designed to ensure watertight performance and mechanical reliability.

Manufacturing Steps

Material Procurement – Sourced from approved IS 2062 certified mills.

CNC Cutting – Plate and pipe sections are cut using CNC plasma for dimensional consistency.

Welding – Performed by certified welders using MIG or SMAW processes per IS standards.

Surface Treatment –

MS versions: Two coats of epoxy primer or enamel paint.

GI versions: Full hot-dip galvanisation per IS 4736 or IS 2629.

Quality Inspection –

Dimensional check for squareness and weld alignment.

Coating thickness measurement.

Installation Insights for Engineers

Proper installation ensures performance.

A puddle flange is not meant to stop internal flow — it stops external leakage along the pipe-concrete interface.

Key Installation Guidelines of Puddle Flanges

Step 1: Weld the puddle flange firmly onto the pipe before placing the pipe through the formwork.

Step 2: Ensure the flange plate is centrally aligned and square to the pipe axis.

Step 3: Embed the flange plate fully within the concrete pour.

Step 4: Compact concrete properly around the flange area to avoid honeycombing.

Step 5: For GI versions, reapply zinc-rich paint on welded joints post-installation.

Recommended Concrete Embedment Depth:

Minimum 75 mm on both sides of the flange plate.

Note: Never allow bitumen or non-cementitious coatings to form between the flange plate and concrete surface — this weakens the mechanical bond.

Typical Applications of Puddle Flanges

| Sector | Application Example | Benefit |

|---|---|---|

| Water Infrastructure | RCC tanks, STPs, and manholes | Prevents seepage along pipe penetrations |

| Fire Fighting Systems | Underground and riser lines | Maintains watertight pressure boundary |

| Commercial Basements | Drainage and water lines | Protects RCC from moisture intrusion |

| Industrial Projects | Cooling lines, pump rooms | Ensures leak-free concrete interfaces |

Pro Tip for Site Engineers:

Use GI puddle flanges for all external or below-ground walls to ensure long-term corrosion protection.

Vijay Sales Corporation – Your Technical Partner

Since 1961, Vijay Sales Corporation has been supplying precision-engineered pipes, fittings, and flanges to some of India’s largest infrastructure and industrial projects.

Our legacy is built on technical competence, tested products, and transparent documentation — not marketing claims.

Why Industry Professionals Trust Us:

60+ years of domain experience.

Stocking and fabrication under one roof.

Immediate dispatch for standard sizes.

Guided selection support by our in-house technical team.

Explore our complete Flanges range at Vijay Sales Corporation

“Vijay Sales Corporation’s puddle flanges performed perfectly during our basement tank installation at our Joy Grand Project in Mohali. The galvanised finish was uniform, and their engineering team helped us verify embedment spacing as per our drawings. The result: zero seepage during hydro testing.”

— Mr. Singh, Dashmesh Builders

Get the best Prices of Flanges at Vijay Sales Corporation

Ready to Discuss Your Project Requirements?

Whether you need standard-size puddle flanges or custom designs to match RCC layouts, our engineering team can guide you every step of the way.

Every flange we deliver protects a structure — and every project we serve strengthens our commitment to quality.

Frequently Asked Questions on Puddle Flanges

What is the role of a puddle flange in concrete structures?

A puddle flange provides a watertight seal at pipe penetrations through concrete walls or slabs. It prevents water from tracking along the outer pipe surface — protecting both the structure and the pipeline from leakage.

What materials do you use for puddle flanges?

We manufacture puddle flanges in Mild Steel (MS) and Hot-Dip Galvanized Mild Steel (GI). These offer high weldability, structural strength, and long-term corrosion protection for underground or damp conditions.

Are puddle flanges designed to handle pressure?

Puddle flanges are primarily meant for structural sealing rather than pressure containment. They are suitable for non-pressure or low-pressure applications (up to PN 10), depending on pipe design and installation.

How should a puddle flange be installed?

Weld the puddle flange to the pipe before positioning it through the formwork. Ensure the plate is fully embedded within the concrete and compacted properly around it. Avoid any bituminous or non-cementitious coating between the flange and concrete face.

When should I choose GI over MS puddle flanges?

Use GI puddle flanges for all external, underground, or moisture-exposed applications. The hot-dip galvanised coating provides a zinc barrier, preventing corrosion and extending service life.

Can you fabricate custom puddle flanges?

Yes. We fabricate to site drawings and consultant specifications. Our team can also assist with sizing, embedment depth, and installation guidelines for project-specific conditions.